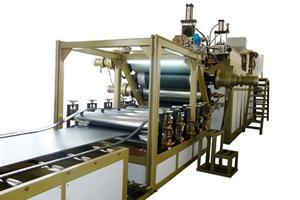

Foam Sheet Extrusion Line (PE, PP, ABS, EVA Foam Sheet Production)

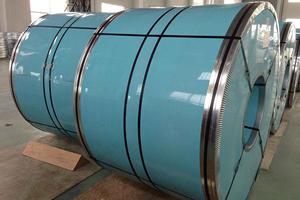

The foam sheet extrusion line is designed for extruding PE, PP, ABS, and EVA foam sheets. This extrusion line primarily uses PE to produce 3 layer co-extrusion sheets, which are hard sheets with top and bottom layers, and a middle layer made of a micro foam material that features a fine foaming density of 0.5-0.75g/cm3. With this structure, the sheet features a light weight and sufficient hardness. The sheets are mainly used for steel (galvanized sheet, stainless steel plate, cold rolled sheet) packing, light rail packing and other packing applications.

Product parameters| Model No. |

|

| Product layer number | Three-layer sheet |

| Product thickness tolerance | ±0.01mm |

| Useful width | 1200-2800mm (Max.) |

| Thickness range | 1mm-4mm |

| Output capacity (Max.) | 1000kg/h(gross) |

| Screw size | main screw size: 180mm Two auxiliary screw size: 90mm |

| Machine size(LxWxH) | 28Mx3Mx2.5M |

| Motor power | Main motor power: 220kw |

Screw Design

The screw structure is designed according to different plastic materials. In this design, plastic is heated until it's turned to a liquid, in a process known as a plasticizing method. Plastic materials undergo different

plasticizing methods based on different designs and requirements, such as the venting for acrylonitrile butadiene styrene (ABS), uniform and fine foam structure, more pores for foamed polypropylene and polyethylene.

Different screw designs for different plastic materials help to reduce the reaction force of bearings. Because of that, the torque on the electronic motor is generally less, allowing for a better energy saving effect.

This is the main motor of the three-layer co-extrusion blown film machine, with the main screw's diameter being 180mm, and the auxiliary screw's diameter of 90mm.

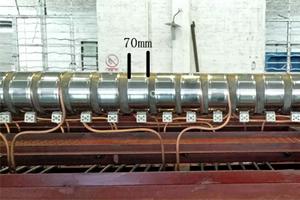

Heating system

Xiaoshan's plastic sheet extrusion line utilizes a unique screw heater with a width of 70mm. Fine gaps between the heaters achieve a uniform heating and stable temperature control, which

are both critical for the foaming process.

Temperature control system

Our plastic sheet extrusion line also utilizes a unique copper pipe oil cooling system for screw cooling, which can precisely control the temperature in a range of ±1

℃ in order to achieve an optimum plasticizing effect. Different from other systems that typically use a wind cooling process, Xiaoshan uses an oil cooling process. Wind cooling is not always

effective, as the cooling process is not stable because it relies on seasonal wind temperatures, which in turn means product quality will vary. With oil cooling, however, the cooling process is stable, making this plastic

extrusion line ideal for even medical grade PCL (Poly-caprolactone) low temperature thermoplastic sheet production with a temperature lower than 90℃. The

oil cooling system requires only a pump requiring 0.37Kw-1.5Kws of power.

Gearbox configuration

Xiaoshan uses a gear box with increased capacity. For example, for screws with a diameter of 120mm, the SJ280 gearbox works, but the SJ315 is an even better choice as it does not

easily become damaged under a full load. Thus, with a full load, the SJ315 can be used for longer periods of time with less maintenance requirements to the benefit of both the customer and the supplier.

Product advantages

The foam sheet extrusion line uses three screws to extrude plastic sheets of the same or different materials both evenly and simultaneously. The line features a high capacity and

good plasticizing effectiveness, stable operation, as well as easy operation and maintenance. The resulting sheet has a fine, smooth surface with a strong corrosion and leakage resistance, as well as added strength.

The sheet's maximum width is 4.5m, and sheet thickness is 0.8-3.5mm. The line also be customized upon request.

Xiaoshan supplies the most advanced micro foam sheet extrusion line. Foaming materials include TPU, TPE, TPR, EVA, PE, PP, PS and ABS.